Case Studies

Industry

Agriculture and biotechnology

Company

3,000 employees in Brazil

Profile

Global supplier of agricultural products, with focus in the development of seeds and crop protection products

Works Goal

Improve performance and decrease risk of incidents with the use of abrasives within Monsanto facilities

Approach and SolutionPresented to the Client by Walter

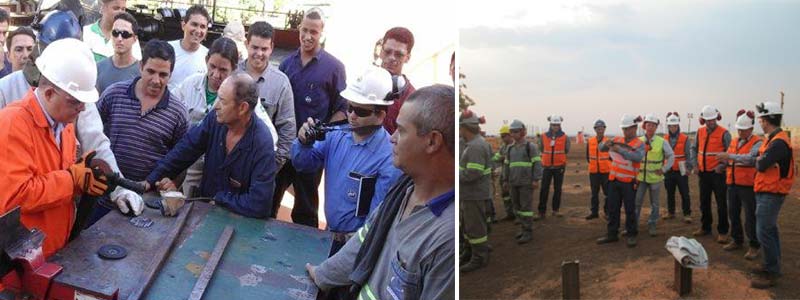

Promote Safety Seminars for training operators to safely use abrasives, reducing hazards and increasing safety in the workplace.

Another success story

Monsanto’s vision is to be the company most recognized to contribute to the success of farmers, becoming their preferred partner in providing integrated technologies, products and service solutions for modern agriculture, and as a promoter of agricultural development.

Present in Brazil since 1963, Monsanto employs about 3,000 people in 38 facilities located in several states and in the Federal District.

The increasing market demand requires constant plants expansions and improvements.

The maintenance area ensures the smooth operation of the plants, minimizing downtime or interruption of production. Delays caused by repairs and maintenance of machinery and equipment affect the productivity.

Reducing hazards and accidents, and consequent absence of work is a constant challenge.

Commitment to collaborators safety

Gleiser Gonçalves, ESH Coordinator of the Engineering Department of Monsanto, talks about the partnership with Walter started in mid 2014. “We were seeking a supplier of high quality abrasives that offered the best safety standard in the market. The partnership started in that same year, with training and safety seminars for all Monsanto operators and outsourced contractors.

As soon as we started the partnership, the performance results changed dramatically. Since we implemented the exclusive use of Walter abrasives, there has not been any incident related to these products. This positive outcome is consequence of the great commitment of Monsanto and Walter in safety training, with about 1,000 operators qualified so far. Training for new employees, and refresher training are regularly offered. .

Conducted by the Walter technical team, Safety Seminars include hands-on workshops, yield evaluation and comparative tests. Attendees can ascertain the superiority of Walter products, and easily realize that the quality of products has a direct impact on safety.

Beyond the line of abrasives, the partnership includes Bio-Circle, division of Walter Surface Technologies that offers innovative solutions for parts cleaning, replacing the use of solvents and providing safe, efficient and sustainable products. There are several Bio-Circle machines installed in four Monsanto facilities, and we have been working to increase the number of machines in the upcoming year.”

Mr. Ronan Pinheiro, from GAP Gestão Ambiental e Projetos, provides Safety Advisory Services to Monsanto. He has contributed to the standardization of processes and products related to the use of sanders and abrasives.

According to him, the two best strategies for reducing the incident rate are training operators and the use of first-line products. He affirms that the technical support offered by Walter and the quality of its products play a big role in the continuous improvement process.

Gleiser Gonçalves - ESH Coordinator - Monsanto

Count on Walter to improve the productivity and safety of your collaborators. Please contact us for scheduling a technical visit, where we will introduce solutions to improve productivity, reduce cost and increase safety in the use of abrasives.